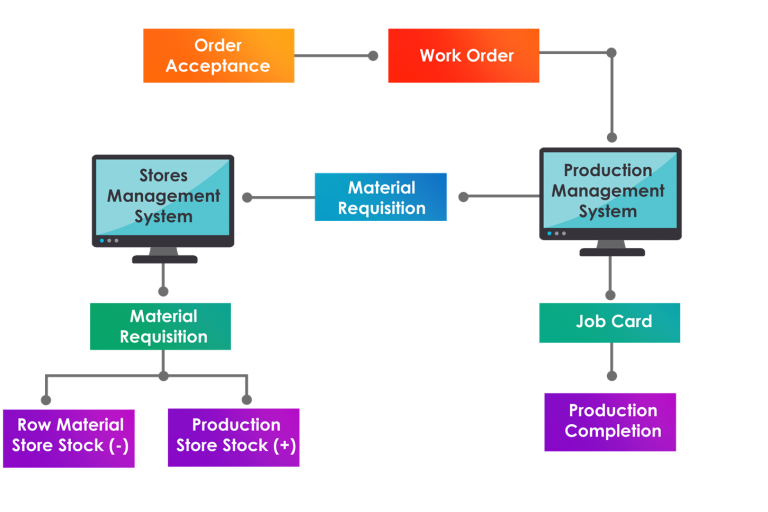

In the ERP Production module, start with taking customer order

Next step of production create a work order with

details about what needs to be made. This turns into job cards that guide each production task. When

everything's done, a material requisition tells us what materials were used. We then update our raw material

stock, subtracting what was used and adding any leftovers. It's like a production journey from order

to materials, all managed smoothly in the ERP system.